| Torque sensor introduction |

| Hits:45866 AddTime:2023/6/20 9:23:29 |

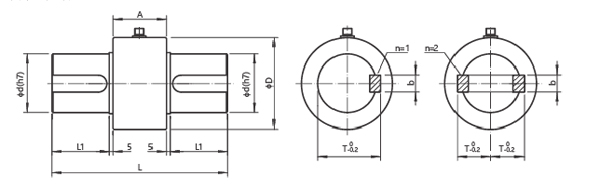

ZJ torque speed sensor (dynamic) adopts strain gauge measurement technique.The electrical signal of elastic shaft under torsion can be measured by providing power for the strain gauge bridge. After amplified,and voltage/frequency conversion, the strain signal is converted into the frequency signal directly proportional to torsional strain. Product features:

1. Torque measurement;energy and signal non-contact transmission; output signal digitized . Main Function and Performance Index:

Torque indication error: <± 0.2 % F · S

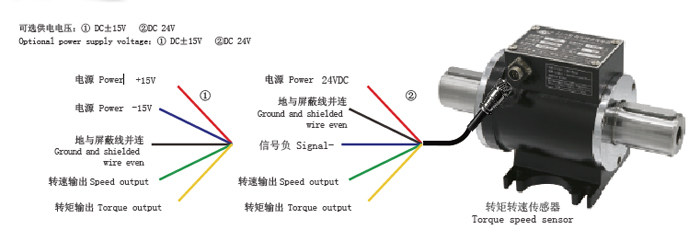

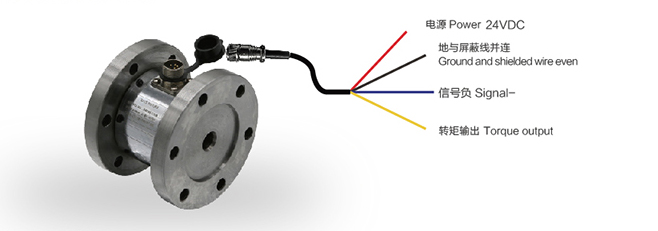

Plug connection and lead definition

In the interests of safety, the transducer should only be operated as described in the

The torque speed sensor is not a safety element within the meaning of its designated

The transducer corresponds to the state of the art and is failsafe. The torque speed

Everyone involved with mounting, starting up, maintaining, or repairing the torque speed

The scope of supply and performance of the torque speed sensor covers only a small

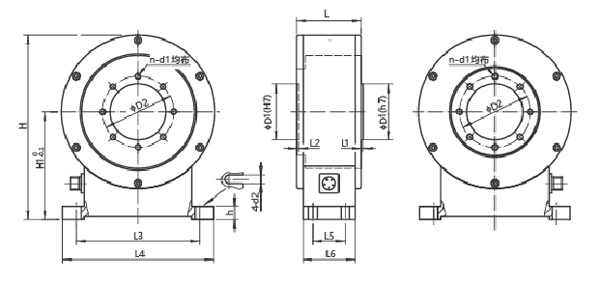

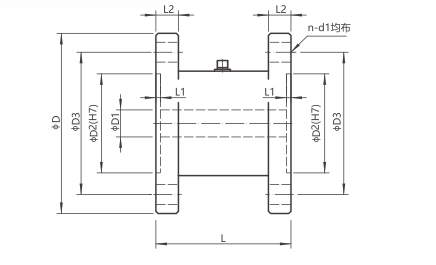

The input and output of ZJ-AP disk torque sensor are connected by flanges (one end of which must be rigidly connected). Because this type of sensor does not use bearings, it can effectively avoid measurement errors caused by bearing heating. It is suitable for high-speed rotation or for situations requiring shorter axial dimensions.

Range 5000 ~ 2000K N m Parameters Call for 5000 ~ 2000K N m Parameters

Signal Output and Signal Acquisition 1. The basic form of torque signal output: Disc Torque Sensor Secondary Instrument · Square wave signal, pulse signal. · Voltage analog signal output or current analog signal output (unidirectional and static torque measurement) can be made according to user's needs.

2. Torque signal processing form: · The frequency signal output by the torque sensor is sent to the frequency meter or digital meter to read directly the frequency signal or voltage and current signal proportional to the torque. · Torque and frequency signals of the torque sensor are sent to the secondary instrument of the single chip computer, which directly displays the real-time torque value, speed and output power value and RS232 communication signal. · The frequency signals of torque and speed are sent directly to the computer or PLD for processing.

Technical Indicators: 1. Frequency Response 100 Us 2. Insulation strength: 200M(100V) 3. Power Supply: DC12-24V Current (> 50mA) 4. Output signal: current 4-20 mA, voltage 1-5 V, Frequency square wave 10KHz/+5KHz (optional) 5. Internal resistance of torque sensor: 1000_

Usage and Characteristics Measurement and Control of Torque Torque Value Applicable to Static and Discontinuous Rotation

Range: 1000, 2000, 3000, 5000N.m.

ZJ-FZ flanged static torque sensor is widely used in static torque testing system such as test machine, torque wrench, steering gear, electric actuator, valve, hydraulic pressure, etc. It is favored by users because of its excellent stability, high measurement accuracy and high cost performance.

|

| 【Refresh】【Favorites】【Print】 【Close】 |

| Previous:ZJ-A standard Torque Speed Sensor(Dynamic torque sensor) Next: NO |

- Torque speed sensor

- torque speed sensor

- Magnetic powder clutch

- Magnetic powder brake

- Tension control system

- Deviation control system

- Safety chuck

- Air shaft

- Eddy current brake

- Hysteresis brake

- Hysteresis clutch

- Hysteresis dynamometer

- Eddy current dynamometer

- Electric dynamometer

- Magnetic powder dynamometer

- Hydraulic dynamometer

- Chassis dynamometer

- Drill pipe test bench

- Actuator, worm gear box, test bench

- Engine, axle, gearbox, PTO test bench

- Reducer test bench

- Traction machine test bench

- Motor test bench

- RV, Harmonic and Planetary Test Bench

- Hydraulic pneumatic motor test bench

- Hydraulic wrench test bench

- Testing software

- Slewing bearing test bench

- Acquisition instrument

- New energy vehicle transmission test bench

- Non-standard custom test bench

- High and low temperature test chamber

- coupling

- Industrial chiller